In today’s rapidly evolving industrial landscape, performance and precision have become key factors in choosing motion control components. Among the most valued contributors to this field are Magnetic Powder Clutch manufacturers , who play a vital role in delivering efficiency and stability to production lines worldwide. As a leading name in this space, cbbmachine continues to develop clutch systems that align with the latest technological standards and operational needs.

Magnetic powder clutches offer unique advantages over traditional mechanical systems. They use magnetic particles and electromagnetic force to transmit torque, ensuring contact-free operation. This design minimizes wear and tear while enabling smooth torque control across various industrial processes, from printing and packaging to textile and film machinery. For businesses aiming to achieve consistent output with minimal maintenance, these clutches represent a dependable solution.

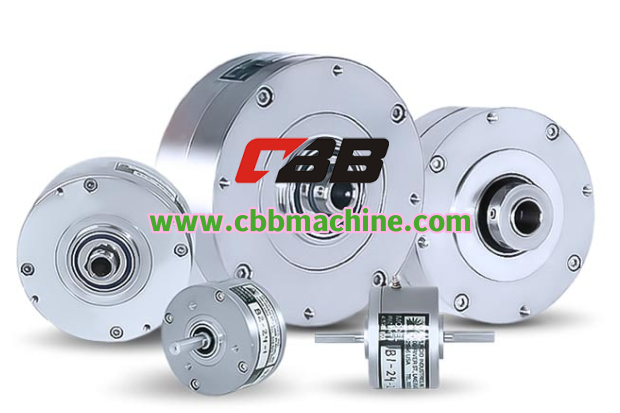

The growing demand for automation across sectors has fueled innovation among manufacturers of these clutches. Instead of relying on one-size-fits-all products, top companies focus on engineering solutions tailored to specific applications. This ensures that machines operate with optimal responsiveness, energy efficiency, and control. In this regard, cbbmachine stands out by offering a comprehensive selection of clutch models that suit diverse industrial environments.

A major benefit of working with established magnetic powder clutch manufacturers lies in their ability to provide both customization and technical expertise. Whether a client requires compact clutches for limited-space installations or robust systems for high-torque operations, experienced manufacturers can adapt their designs accordingly. Moreover, brands like cbbmachine are known not only for product quality but also for dedicated service and support throughout the customer journey.

Clutches developed using magnetic powder technology are particularly well-suited to applications requiring frequent starts and stops. Their rapid response to changes in load and speed makes them ideal for precision-driven processes. This capability also contributes to extended machine life and reduced operational costs, which are crucial factors for manufacturers looking to optimize ROI over time.

Advanced manufacturing practices have further enhanced the performance of these systems. Today’s clutches boast improved heat dissipation, noise reduction, and compact form factors without compromising on power. These innovations allow for seamless integration into both legacy and next-generation equipment, making them a forward-compatible choice for progressive factories.

Sustainability is another growing concern across industries. In this context, magnetic powder clutches support greener operations by reducing mechanical friction and requiring less energy. As businesses aim for lower carbon footprints, these clutches contribute to eco-efficient manufacturing without sacrificing productivity.

What sets cbbmachine apart among global competitors is not only its technical capability but also its commitment to continuous improvement. With years of research and development, the company has built a solid reputation for delivering dependable products that adapt to market shifts and customer demands. Their focus on both function and innovation positions them as a preferred partner in automation and motion control.

As production processes become more complex and require ever-more-precise control, the importance of choosing the right magnetic powder clutch manufacturer becomes clear. It’s not just about purchasing a component—it’s about forming a relationship with a partner who understands the dynamics of industrial performance and is equipped to support long-term success.

Welcome to visit our website: www.cbbmachine.com