There exists a memorable yet unfortunate experience familiar to countless individuals: the catastrophic failure of a disposable kraft box during what should be an enjoyable meal occasion. These incidents transcend ordinary inconvenience, representing fundamental breakdowns in packaging reliability. The visual of sauce dripping through failing seams or watching sides bulge ominously before surrendering creates lasting negative impressions. For food businesses, these moments translate directly to customer dissatisfaction and dissatisfaction and potential loss of repeat patronage. The psychological impact shouldn't be underestimated either - when packaging fails, it casts doubt on the overall quality perception of both the meal and the establishment serving it. Such occurrences highlight the delicate balance between sustainable material use and practical performance requirements in food service applications. These failures undermine confidence in both the product and the brand it represents.

Moisture management represents perhaps the greatest challenge in kraft packaging performance. Once oils or sauces penetrate the paper fibers, the material loses tensile strength rapidly. This phenomenon explains why some containers appear perfectly adequate initially but deteriorate dramatically during the course of a meal. The problem intensifies with certain cuisine types known for their liquid components and higher fat content. The intersection of heat, moisture, and mechanical pressure creates the perfect conditions for structural compromise. Manufacturers attempting to cut corners exacerbate these issues through inconsistent adhesive application, improper seam overlapping, or inadequate curing times during production. The consequence manifests as slow saturation marks spreading across the container exterior, followed by sudden tearing or complete bottom drop-out. Even properly constructed boxes can fail if the paper stock lacks sufficient density or the manufacturing process creates micro-perforations that become failure initiation points under stress conditions.

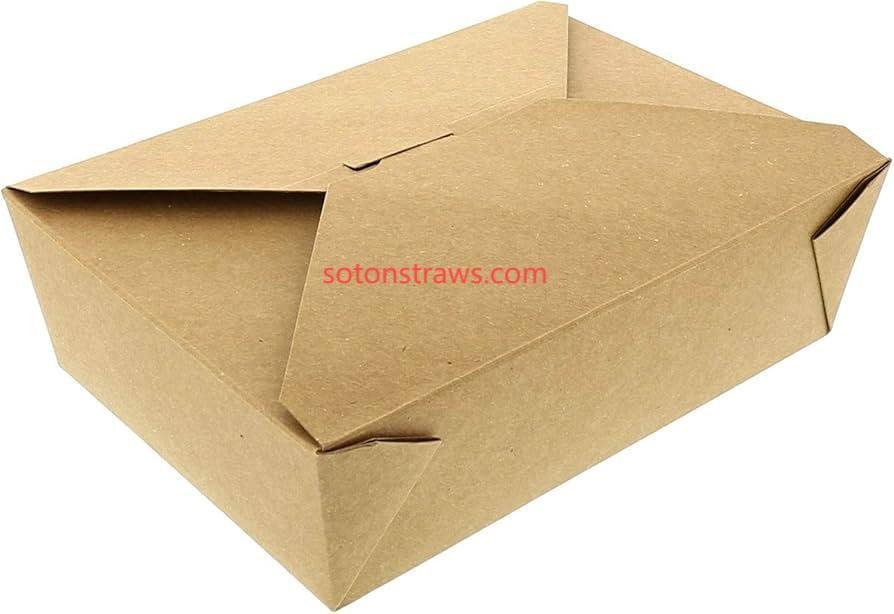

Selecting appropriate packaging involves evaluating several performance characteristics beyond superficial appearance. Examine how corners are reinforced and whether edge bonding appears consistent and substantial. Consider how the container feels when lifted from different angles - does it maintain rigidity or flex concerningly? Assess the closure system's security and whether it distributes stress evenly across the surface area. A well-designed disposable kraft box incorporates multiple defensive strategies against failure: appropriate material thickness, intelligent structural geometry, and effective barrier treatments where necessary. These elements work synergistically to prevent the all-too-common scenario of collapsed containers and ruined meals.

Our team at Soton approaches packaging design with scientific rigor and practical understanding. We've developed proprietary methodologies that enhance the natural strengths of kraft paper while mitigating its inherent limitations. Our disposable kraft box solutions undergo exhaustive real-world simulation testing before reaching customers. We analyze performance under various conditions including prolonged storage, transportation vibration, and variable humidity levels. This comprehensive approach ensures that every container leaving our facility meets exacting standards for durability and leak resistance. We believe your food deserves packaging that protects its quality and presentation from kitchen to final destination. Trust Soton to deliver the robustness your culinary creations deserve.Click https://www.sotonstraws.com/product/ to reading more information.